Damage disputes remain one of the most persistent sources of friction in container logistics. Each dispute delays settlements, absorbs operational time, and weakens trust between depots, transporters, shipping lines, and cargo owners. In most cases, the issue does not originate from the damage itself. It originates from how inspections are documented.

Photo-proof container reports reduce disputes by turning inspections into reliable, traceable records of truth. When condition, location, and timing are captured together at the moment responsibility changes, accountability becomes clear and defensible.

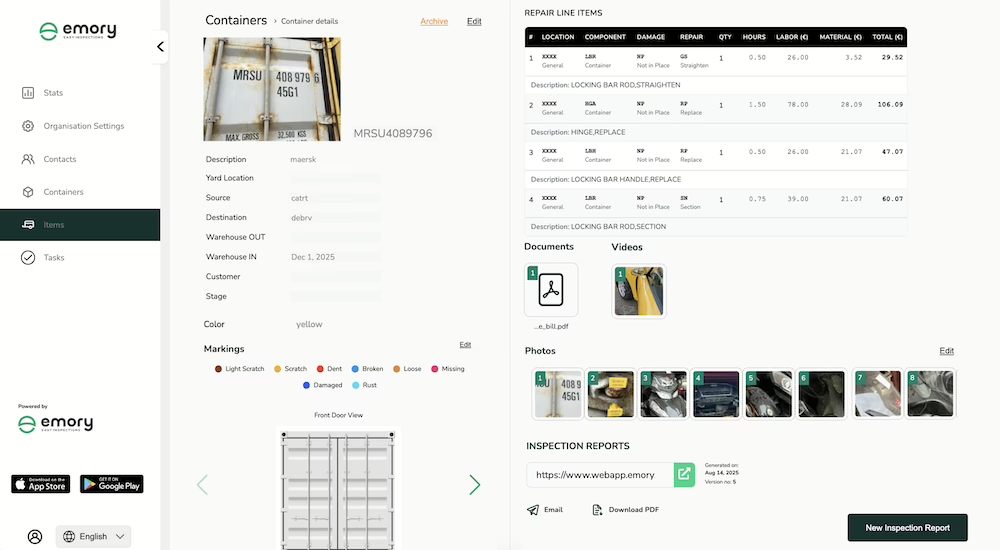

This is the principle behind modern digital inspection workflows and the reason platforms like Emory Pro exist: to make inspections accurate, connected, and dependable in real operational environments.