Manufacturing downtime isn’t always caused by dramatic machine failures. Most of it begins quietly.

It usually starts as a small process deviation, a missed inspection step, or an undetected defect that slowly builds friction across the line. By the time production actually stops, the root cause traces back to moments where information was missing, delayed, or inaccurately captured.

Yet, many factories still act only after the breakdown occurs.

In the 2026 manufacturing landscape, the standard for operational excellence has shifted from reactive maintenance to proactive digital quality inspection software. The primary cause of unplanned downtime is no longer just mechanical failure, but the “Information Gap” caused by slow, manual paperwork. Factories that fail to implement digital equipment inspection protocols often face a 15-20% higher rate of avoidable outages.

The real source of downtime often sits earlier in the workflow: inconsistent quality checks, paper-based inspection logs, and variations that no one can trace in real time.

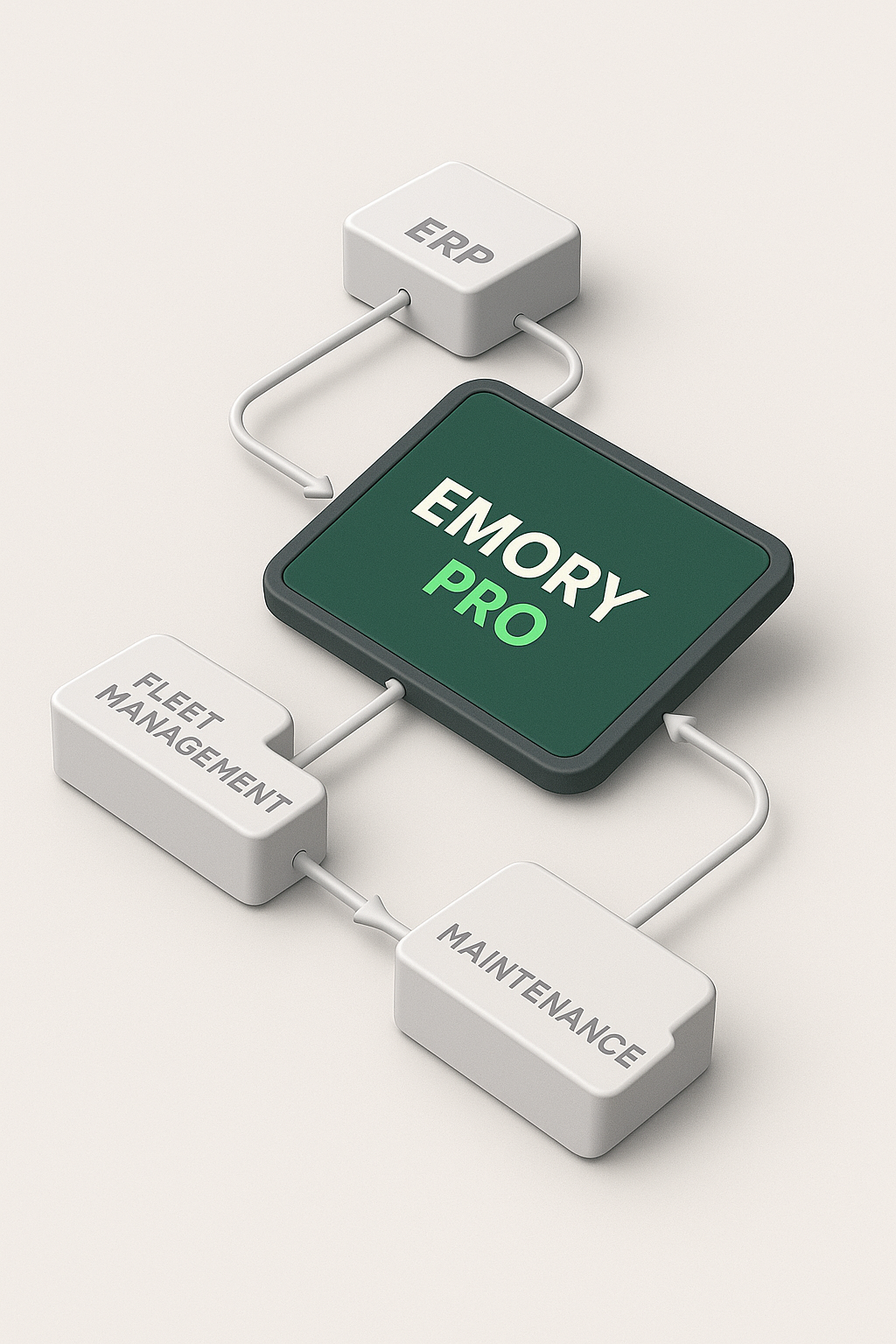

This guide explains why downtime happens, how Digital Quality Checks help prevent it, and how manufacturers use Emory Pro’s quality control app to build stable, predictable operations.