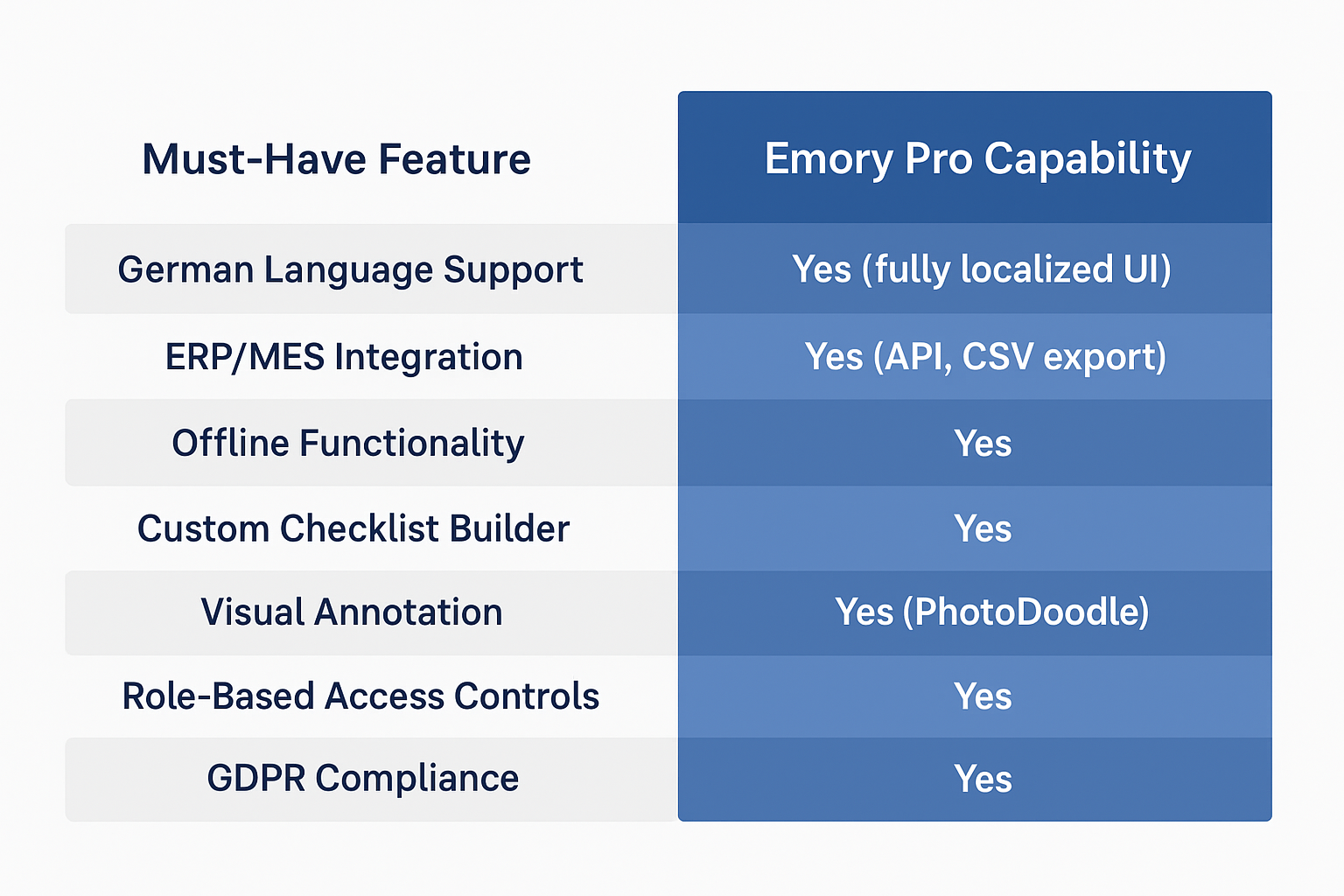

In Europe’s manufacturing sector – from automotive and aerospace to heavy machinery and medical devices – quality control has always been the foundation of global success. For many producers in Germany and across the EU, it’s not just about delivering products; it’s about doing so with precision, traceability, and strict compliance. As Industry 4.0 advances, digital inspection software are becoming an essential part of that equation.

This article looks at how platforms like Emory Pro are helping manufacturing teams enhance quality control processes.

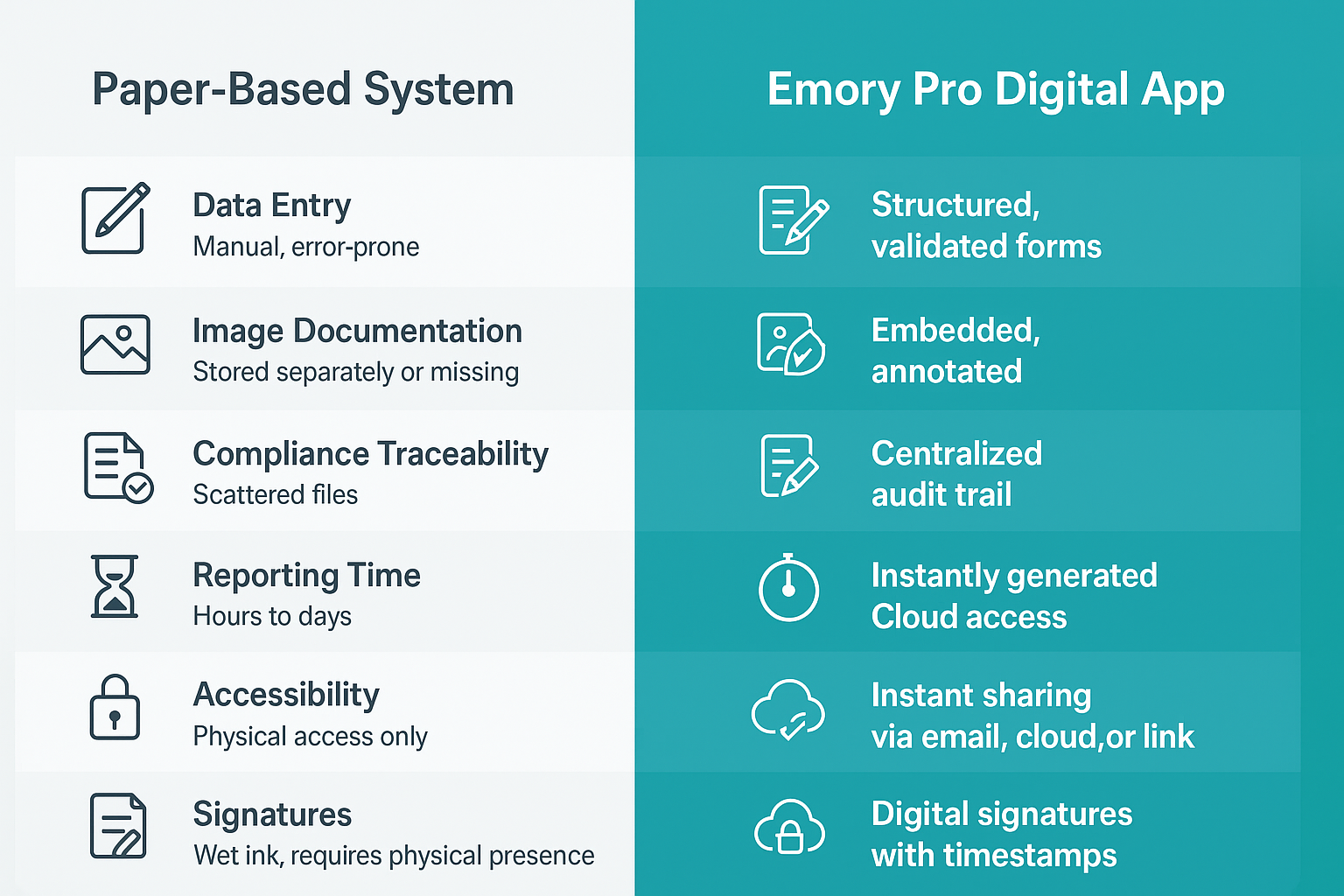

The app, available on iOS, Android, and via detailed web documentation, replaces paper checklists with intelligent, mobile-first workflows.